History of Fiber-Reinforced Concrete - The use of various fibers in construction can be traced back to ancient times. Consider the Roman Pantheon’s dome, where animal hairs were found. Even earlier, plant fibers were used in the construction of adobe houses. The explosive development of fiber-reinforced composites began in the 1960s, a trend that continued to strengthen with the advent of new materials and applications. Fiber reinforcement has influenced concrete technology from the beginning, but its widespread use dates to the 1980s and 1990s. Initially, steel and glass fibers were used, but with advancements in polymer technology, plastic fibers also gained prominence. The experience with steel fiber-reinforced concrete informed the development of synthetic fibers with the aim of increasing concrete's toughness. Today, polymer fibers are indispensable in many architectural applications due to their excellent resistance to de-icing salts and corrosion.

Use of Plastic Fibers - Decades of experience and development-related studies allow for the selection of the appropriate type and quantity of fibers for a given project. The type of synthetic fiber used is determined by the magnitude and conditions of the load, and most importantly, by economic calculations. Fibrillated fibers have proven extremely successful over the past thirty years, but macro polymer fibers are more advantageous for higher loads. Using fiber-reinforced concrete compared to traditional reinforced concrete saves time and money. Plastic fibers improve post-crack strength. The fibers’ role and advantage lie in reducing crack sensitivity, increasing toughness, saving on rebar work, and improving wear resistance.

Diamond Synthetic Fiber for Structural Reinforcement of Industrial Floors

Avers Fiber's Role in Introducing and Applying Fiber Concrete Technology in Hungary

Our company's main profile is the design of fiber-reinforced concrete structures and the manufacture and distribution of the necessary construction fibers. Over the past decades, more than 20 million m² of industrial floors, pavements, and other special concrete structures have been linked to our name. In our projects, reinforcement was either completely omitted, or, in the case of higher loads, fiber reinforcement was combined with reinforcement. The result: less steel, less installation work, faster execution, optimal design, and cost savings. The fibrillated synthetic fiber used for reinforcing industrial floors, pavements, concrete roads, and waterproof structures has been applied in Europe for 40 years and in Hungary for nearly 25 years. No other fibrillated fiber on the market has so much experience, references, and test results. It is an economical alternative to steel fibers and steel mesh. Adding the fiber improves the concrete's mechanical properties, which are utilized in structural designs while considering the relevant regulations of each country. The same fiber reduces shrinkage cracks by 85% compared to concrete without fibers, resulting in a higher density, minimal microcrack tendency, and a 25% reduction in water penetration depth. In addition, High Grade fiber-reinforced concrete increases fracture energy.

Numerous Laboratory Experiments

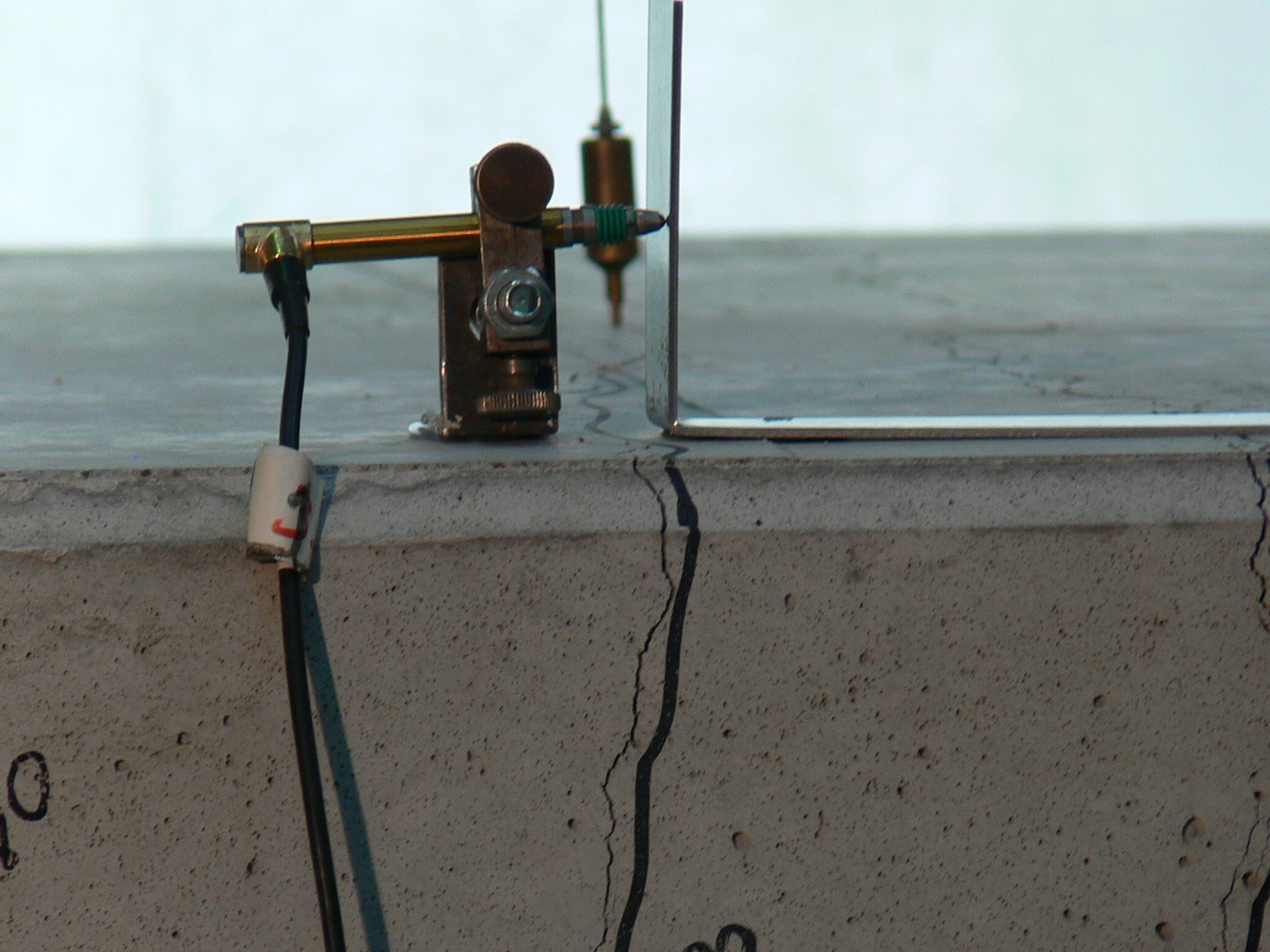

The manufacturer is responsible for knowing the materials used in structural design and commissioning accredited laboratory tests for both the raw materials and fracture tests. The design values used in structural design are the results of numerous beam tests. Safety in using a particular fiber is ensured through these tests. Worldwide unique tests on Concrix ES macrofibers revealed that fibers in a cracked panel under continuous load for several years do not elongate. Our microfibers were tested with a special wind tunnel experiment simulating extreme weather conditions.

Large-panel testing at the Budapest University of Technology with High Grade and Concrix ES synthetic fibers

Technical Advantages of Synthetic Fiber-Reinforced Concrete

- Fiber concrete has higher technical parameters

- Fiber reinforcement increases the flexural-tensile strength of concrete structures

- Steel fibers/mesh can often be completely replaced or reduced

- Our polymer fibers are made of acid and alkali-resistant polyolefin, making them suitable for aggressive and outdoor environments without corrosion issues

- Suitable for any surface finish or coating

- Enables thinner concrete structures and the creation of slender, curved structures

- Significantly reduces the risk of early shrinkage cracks, improving the structures' watertightness

- Optimal load distribution through three-dimensional dispersion

- Environmentally friendly technology

- 30 years of application and design experience

Economic Advantages of Fiber-Reinforced Concrete

- Significant cost savings by replacing or reducing steel mesh/steel fibers

- Often no need for installation concrete

- Faster and more efficient construction with less labor

- Usually no need for concrete pumps

- Structural thicknesses can be reduced depending on the structure

- Low transportation and storage costs

Application Areas of Fiber Concrete Technology

- Industrial floors, screeds

- Pavements, concrete roads

- Precast concrete elements

- Foundation and track slabs

- Watertight concrete structures

- Shotcrete structures

- Special concrete structures - ice rinks, sports fields, floating concrete pontoons, etc.

High Grade fiber-reinforced large-panel industrial floor